Products

Products

- All products

- Cooling system

- Electronic controller cooler

- Air cooling system

- Amplified air injector

- High air injection jet

- Air curtain

- Suction and dust collectors

- Dehumidifier

- High Pressure Spray for Cutting Oil or Water

- Oil mist cooling and spraying device

Customer support center

070-7790-0269

070-7790-0269

MAIL

black1hole@naver.com

black1hole@naver.com

Air cooling system

HOME > Products > Air cooling system

HOME > Products > Air cooling system

Air cooling system

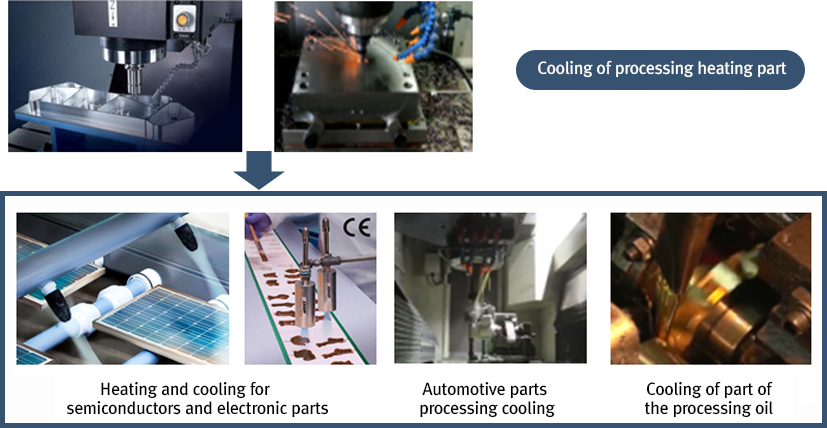

By cooling the heating part in the product production process, it increases productivity by reducing the product production cycle time.

By cooling various heating parts such as machining, it provides many effects in improving parts life and productivity.

It is set for the highest efficiency and is designed to be oxidized and semi-permanently made of stainless steel.

- Machining cutting (CNC lathe, milling, cutting work)

- Mold processing part and tool, grinding work part, etc. - Cooling of the heating part of plastic injection work

- Cooling of heating parts for automobile parts production and welding work

- Cooling of high-temperature heating parts in other product production processes

Detail Information

Device specification

- Machining cutting (CNC lathe, milling, cutting work)

- Mold processing part and tool, grinding work part, etc. - Cooling of the heating part of plastic injection work

- Cooling of heating parts for automobile parts production and welding work

- Cooling of high-temperature heating parts in other product production processes

Local intensive cooling

- Standard: Bracket fixed type

- Option configuration - Cold air spray silencer

- Air filter regulation

- Condensation prevention spray nozzle

- Cold air high pressure injection

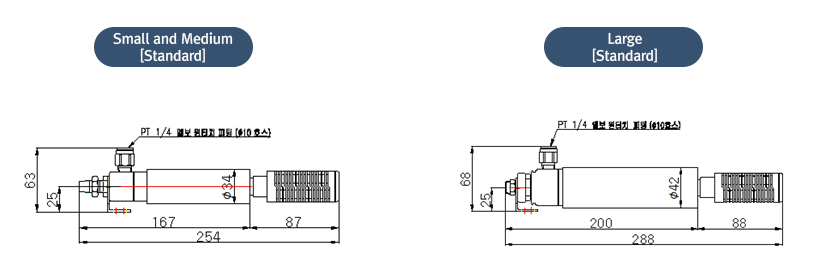

Device specification

Standard: Bracket fixed type

* Supply temperature 23℃, supply pressure 7bar standard

| Model | Supply pressure | Maximum Air Consumption | Cooling Capacity |

|---|---|---|---|

| Kg/cm2 ( PSI ) | SCFM (ℓ/min) | Wh | |

| FAC-M01 | 7 (101) | 8 (146) | 142 |

| FAC-M02 | 12 (207) | 163 | |

| FAC-L01 | 21 (363) | 192 | |

| FAC-L02 | 24 (410) | 350 |

Economy type

| Model | Supply pressure | Maximum Air Consumption | Cooling Capacity |

|---|---|---|---|

| FAC-L01-E | 7 (101) | 21 (363) | 192 |

| FAC-L02-E | 24 (410) | 350 |

The value may vary depending on the temperature and conditions of the supplied air.

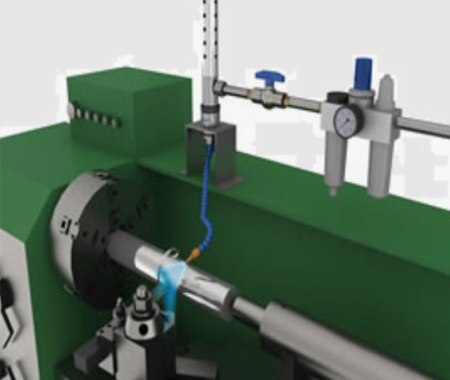

Option: cold air high pressure spray

- Cooling of machining, cutting and drilling work

- Local cooling of high temperature heating part

- CNC lathe, milling. Cooling of the cutting part

- Cooling of tools and grinding work

- Cooling of injection manufacturing part

Cooling Device Application part

- By supplying cold air to the hot heating part of dry processing, it improves the surface roughness and extends the life of the processing tool.

LAYOUT